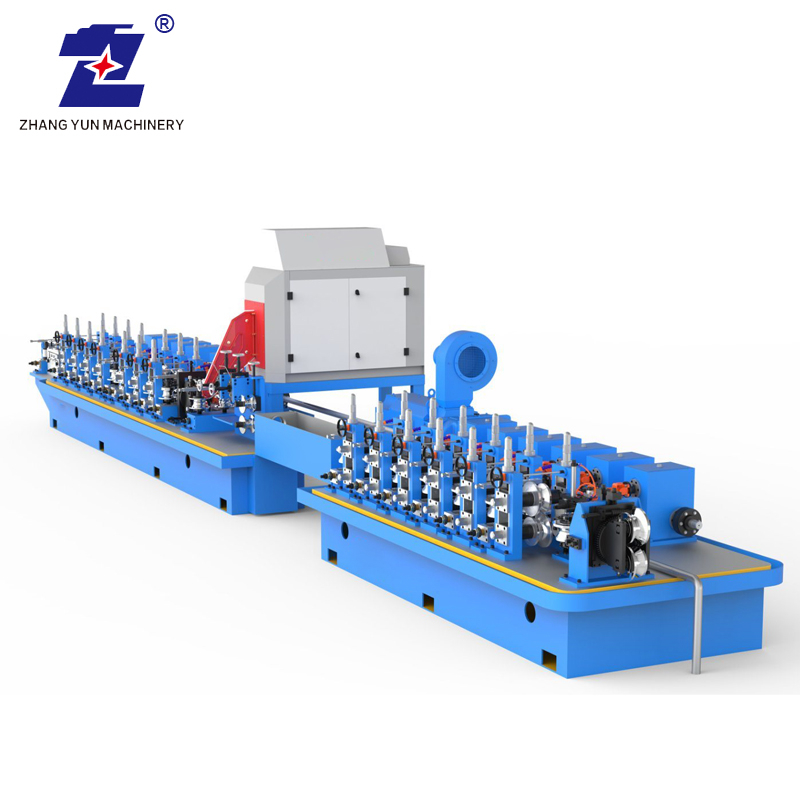

This line is designed to produce various types of elevator guide rail. The elevator guide rail production line has the characteristics of high accuracy and straightness, and our machines can produce different elevator guide rails according to customers' drawings.

Some machine's introductions of elevator guide rail manufacturing equipment.

Guided rails are used in a variety of applications such as highways, railways, and industrial equipment. They are essential components that assure the safety and accuracy of machinery and transportation systems. The production process for guided rails involves several stages and components in order to achieve the desired quality and performance.

Stage 1: Cutting

The first stage in the production of guided rails is the cutting process. The rails are first cut to the required length using a cutting machine. The cutting machine is programmed to cut the rails precisely and accurately to the desired length. After cutting, the rails are then transported by conveyor belts to the next stage in the production process.

Stage 2: Bending

In this stage, the rails are bent to the required shape using a bending machine. The bending machine is designed to bend the rails with high precision and accuracy. The rails are fed into the bending machine by conveyor belts, and the machine uses hydraulic cylinders to bend the rails. The rails are bent to the required angle, which is usually determined by the application. After bending, the rails are cooled to prevent any deformation or warping.

Stage 3: Punching

The third stage in the production process is punching. The rails are punched with holes or slots to enable fixtures and fittings to be attached. The punching machine is designed to punch the rails precisely and accurately to ensure that the rails are suitable for their intended application. The machine is also equipped with a variety of punching tools that can be changed depending on the required hole or slot size.

Stage 4: Grinding

After punching, the rails are then ground to remove any sharp edges or burrs. This is done using a grinding machine that is designed to remove any unwanted material and smooth out the surface of the rails. The grinding machine uses abrasive belts and grinding wheels to achieve the desired finish.

Stage 5: Coating

The final stage in the production process is coating. The rails are coated with a protective layer of paint or epoxy. The coating protects the rails from corrosion and damage caused by exposure to the elements. The coating process involves spraying the rails with the desired coating using a spray machine. The rails are then left to dry and cure, which can take several hours or days depending on the type of coating used.

A high-quality lift guide rail processing production line is essential in manufacturing guide rails that meet strict industry standards. The implementation of advanced technology and tools ensures precision, accuracy, and consistency in every stage of the production process. Efficiency, quality control, and cost-effectiveness are some of the benefits of implementing a high-quality lift guide rail processing production line.

Production Capacity

230400pcs/year (300days/year; 2shifts/day, 8hours/shift) based on T89B/5m

| No. | Description | Model | Qty |

| 1 | Automatic Twisting Machine | ZY-ZDJNJ-II | 1 | set |

| 2 | Automatic Straightening Machine | ZY-ZDJZJ-I | 2 | sets |

| 3 | Rust Removing Machine | ZY-CXJ-II | 1 | set |

| 4 | Painting Machine | ZY-YQJ-II | 1 | set |

| 5 | Drying Room | ZY-HF-II | 1 | set |

| 6 | Planer | ZY-B2016 | 3 | sets |

| 7 | Chip Remover | ZY-PXJ1000 | 1 | set |

| 8 | Automatic Detection Machine | ZY-ZDJCJ-I | 1 | set |

| 9 | Automatic Straightening Machine | ZY-ZDJZJ-I | 2 | sets |

| 10 | Milling Machines | ZY-JGSCX-II | 2 | sets |

| Female Milling Machine | ZY-JGSCX-II | 1 | set |

| Male Milling Machine | ZY-JGSCX-II | 1 | set |

| Drilling Machine | ZY-JGSCX-II | 2 | sets |

| Double-head Countersink Drilling Machine | ZY-JGSCX-II | 1 | set |

| One Conveyor Line | ZY-JGSCX-II | 1 | set |

| 11 | Oiling And Filming Machine | ZY-TYTMJ-II | 1 | set |

| 12 | Transverse Conveyor (A) | ZY-HYJ-II | 9 | sets |

| 13 | Jack traverse Converyor (B) | ZY-DSJ-II | 17 | sets |

| 14 | Longitudinal Conveyor (C) | ZY-ZXJ-II | 8 | sets |

| 15 | Independent Roller | ZY-DLJ-I | 1 | set |

| 16 | Control System |

| 1 | set |

Zhangjiagang City Zhangyun Machinery Manufacturing Co., Ltd. is established in 2002, manufacturer of elevator guide rail processing production line machinery, cold roll forming line machinery and high frequency tube welding line machinery.

Quality Oriented,Technology Innovation is our core concept. Each component of our machines is examined and qualified before assembling; each set of our equipment is fully test run before delivery.

FAQ

1.Q: Are you manufacturer or trading company?

A: We are manufacturer. And we have our own import & export rights.

2.Q: What info you need before you make proposal?

A:Your target type of elevator guide rails; your required production capacity per year; working hours per day, working days per year.

3.Q: What is the MOQ?

A: One set.

4.Q: Do you provide installing and debugging overseas?

A: We send engineers overseas for installation and debugging under client’s request. On line guiding and technical support is for life time.

5.Q: Can you make the machines according to my design or prototype?

A: Yes. We have an experienced engineering team for working out the most suitable design and production plan for the machines you are going to book with us.We can also make the machines according to your design or prototype.

6.Q: How does your factory do regarding quality control?

A: We have Quality Management System Certificate GB/T9001-2016/ISO9001:2015. Each component of our machines is examined and qualified before assembling; each set of our equipment is fully test run before delivery.

7.Q: How can I trust you that machines have passed test running before shipping?

A: 1) We record the test running video for your reference.

2) You are welcomed to observe the test running in our factory.

8.Q: What about your after-sale service?

A: 1) We have an after-sale service team for each customer, including GM, sales Rep, chief engineer, and main engineers for design and making your machines.

2)Overseas after-sale service is available.

3)We provide life time online technical support.

9. Q: What should I do if I just start a new business?

A: Contact us immediately,we provide free consultant pre-sales service.

We are domestic leading factory in elevator guide rail processing equipment field. We are familiar with our machines and we have many successful user cases. We know the development history and the latest trends. We can make the most reasonable proposal for you.

10. Q:Can I visit you factory to check machines on-site?

A: We are manufacturer, we have our own R&D department and workshops for more than 20 years. We warmly welcome your visit and checking machines in our factory.