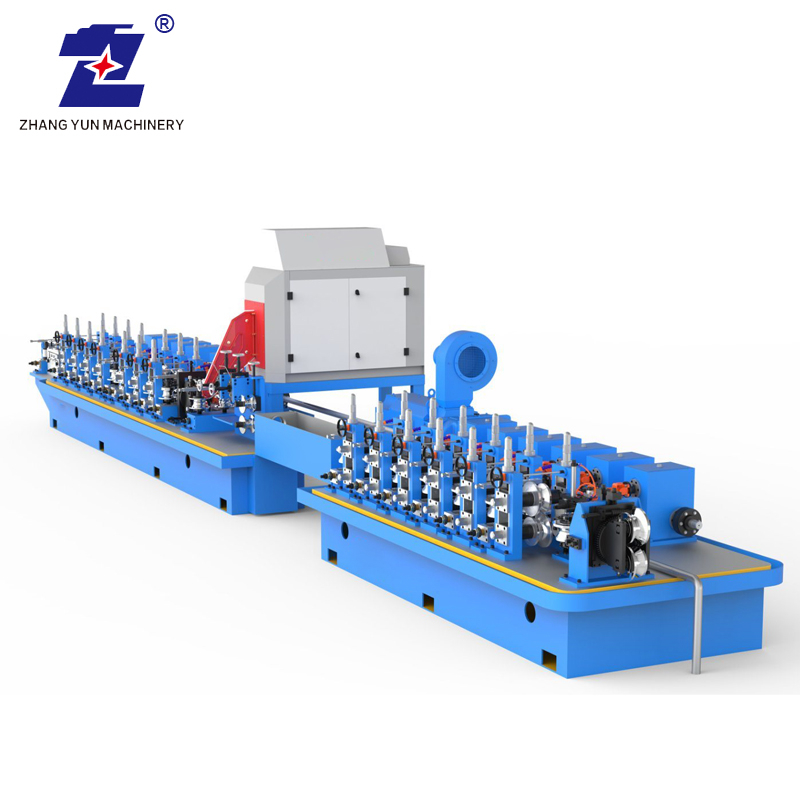

This line is designed to produce various types of elevator guide rail. The elevator guide rail production line has the characteristics of high accuracy and straightness, and our machines can produce different elevator guide rails according to customers' drawings.

Some machine's introductions of elevator guide rail manufacturing equipment

The manufacturing process for elevator guide rails is complex and requires precision engineering. The rails are typically made from steel rods that are drawn, straightened, and cut to the required length. The ends of the rods are then milled to precise dimensions, and holes are drilled for fastening the guide rails to the elevator car and the hoistway walls.

After the guide rails have been prepared, they are usually sent for surface coating. This involves applying a layer of polyurethane to the rails, which helps reduce noise and friction when the elevator car moves up and down the lift shaft. The polyurethane coating also helps protect the guide rails from wear and tear, ensuring their longevity and durability.

Once the coating has been applied, the guide rails are fitted with brackets and fasteners, which will enable them to be fixed securely to the hoistway walls. The installation of the rails is a crucial step in the manufacturing process, and it requires skilled technicians and engineers to ensure that the rails are aligned correctly and securely fastened in place.

The final step in the manufacturing process is testing and quality control. The guide rails undergo rigorous testing to ensure that they can support the weight of the elevator car and that they function safely and smoothly. Manufacturers also perform quality control checks to ensure that the guide rails meet all the necessary safety standards and regulations.

In recent years, some manufacturers have begun to use advanced computerized manufacturing techniques to produce elevator guide rails. Computer-aided design (CAD) and computer-aided manufacturing (CAM) technologies enable manufacturers to create highly precise and customized guide rails that meet the specific requirements of individual lift systems.

Production Capacity

230400pcs/year (300days/year; 2shifts/day, 8hours/shift) based on T89B/5m

| No. | Description | Model | Qty |

| 1 | Automatic Twisting Machine | ZY-ZDJNJ-II | 1 | set |

| 2 | Automatic Straightening Machine | ZY-ZDJZJ-I | 2 | sets |

| 3 | Rust Removing Machine | ZY-CXJ-II | 1 | set |

| 4 | Painting Machine | ZY-YQJ-II | 1 | set |

| 5 | Drying Room | ZY-HF-II | 1 | set |

| 6 | Planer | ZY-B2016 | 3 | sets |

| 7 | Chip Remover | ZY-PXJ1000 | 1 | set |

| 8 | Automatic Detection Machine | ZY-ZDJCJ-I | 1 | set |

| 9 | Automatic Straightening Machine | ZY-ZDJZJ-I | 2 | sets |

| 10 | Milling Machines | ZY-JGSCX-II | 2 | sets |

| Female Milling Machine | ZY-JGSCX-II | 1 | set |

| Male Milling Machine | ZY-JGSCX-II | 1 | set |

| Drilling Machine | ZY-JGSCX-II | 2 | sets |

| Double-head Countersink Drilling Machine | ZY-JGSCX-II | 1 | set |

| One Conveyor Line | ZY-JGSCX-II | 1 | set |

| 11 | Oiling And Filming Machine | ZY-TYTMJ-II | 1 | set |

| 12 | Transverse Conveyor (A) | ZY-HYJ-II | 9 | sets |

| 13 | Jack traverse Converyor (B) | ZY-DSJ-II | 17 | sets |

| 14 | Longitudinal Conveyor (C) | ZY-ZXJ-II | 8 | sets |

| 15 | Independent Roller | ZY-DLJ-I | 1 | set |

| 16 | Control System |

| 1 | set |

Zhangjiagang City Zhangyun Machinery Manufacturing Co., Ltd. is established in 2002, manufacturer of elevator guide rail processing production line machinery, cold roll forming line machinery and high frequency tube welding line machinery.

Quality Oriented,Technology Innovation is our core concept. Each component of our machines is examined and qualified before assembling; each set of our equipment is fully test run before delivery.