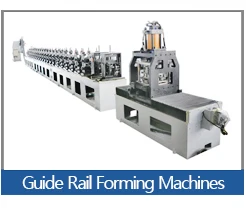

A guide rail production line is a manufacturing system designed to make the production of guide rails efficient and cost-effective. Guide rails are critical safety components that guide and protect vehicles on highways and other roads, especially in curves or steep slopes. They are made of different materials, including reinforced concrete, steel, and plastic. The guide rail production line is a complex system comprised of several stages that transform raw materials into finished guide rails.

The guide rail production line consists of many components that work together to create the finished product. These components include raw materials, machinery, and personnel. In general, the production line begins with the raw materials, which may be delivered to the production site in bulk or pre-processed forms. Once the raw materials are accepted, they are processed using various tools and machinery to create the finished product.

The production process of guiderails involves the following steps:

1. Material Selection: This is a crucial step in the production of guiderails. It is essential to choose the right materials that will withstand the harsh environmental conditions on the road, such as impact forces, moisture and UV rays. Common guiderail materials include steel, plastic, and concrete.

2. Cutting: Once the raw materials have been selected, they are cut into the desired length or size. Cutting is done using different machines, depending on the type of material.

3. Bending: After cutting, the materials are bent using bending machines to form the guiderail shape. The bending machines are designed to bend or shape materials with high precision and accuracy.

4. Welding: The bending process allows for the formation of various guiderail shapes. The next step is to weld the different sections of the rail together. Welding is done using high-quality welding machines that produce strong and durable welds.

5. Galvanisation: Galvanisation is a process of coating steel rails with a protective layer of zinc. It is done to prevent rust and corrosion, which can weaken the guiderail's structure and reduce its safety. Hot dip galvanizing is the most common method of galvanizing guiderails.

6. Painting: After galvanizing, the guiderails are painted with reflective paint. The paint enhances the guiderail’s visibility at night, making it easier for drivers to see the road edge.

7. Testing: After the guiderails are assembled, they undergo various tests to ensure that they meet the required standards. These tests may include compression tests, bending tests, and impact tests.

8. Packaging: Finally, the guiderails are packed in crates or pallets for transportation to their final destination. Proper packaging prevents damage to the guiderails during transportation.

Production Capacity

230400pcs/year (300days/year; 2shifts/day, 8hours/shift) based on T89B/5m

| No. | Description | Model | Qty |

| 1 | Automatic Twisting Machine | ZY-ZDJNJ-II | 1 | set |

| 2 | Automatic Straightening Machine | ZY-ZDJZJ-I | 2 | sets |

| 3 | Rust Removing Machine | ZY-CXJ-II | 1 | set |

| 4 | Painting Machine | ZY-YQJ-II | 1 | set |

| 5 | Drying Room | ZY-HF-II | 1 | set |

| 6 | Planer | ZY-B2016 | 3 | sets |

| 7 | Chip Remover | ZY-PXJ1000 | 1 | set |

| 8 | Automatic Detection Machine | ZY-ZDJCJ-I | 1 | set |

| 9 | Automatic Straightening Machine | ZY-ZDJZJ-I | 2 | sets |

| 10 | Milling Machines | ZY-JGSCX-II | 2 | sets |

| Female Milling Machine | ZY-JGSCX-II | 1 | set |

| Male Milling Machine | ZY-JGSCX-II | 1 | set |

| Drilling Machine | ZY-JGSCX-II | 2 | sets |

| Double-head Countersink Drilling Machine | ZY-JGSCX-II | 1 | set |

| One Conveyor Line | ZY-JGSCX-II | 1 | set |

| 11 | Oiling And Filming Machine | ZY-TYTMJ-II | 1 | set |

| 12 | Transverse Conveyor (A) | ZY-HYJ-II | 9 | sets |

| 13 | Jack traverse Converyor (B) | ZY-DSJ-II | 17 | sets |

| 14 | Longitudinal Conveyor (C) | ZY-ZXJ-II | 8 | sets |

| 15 | Independent Roller | ZY-DLJ-I | 1 | set |

| 16 | Control System |

| 1 | set |

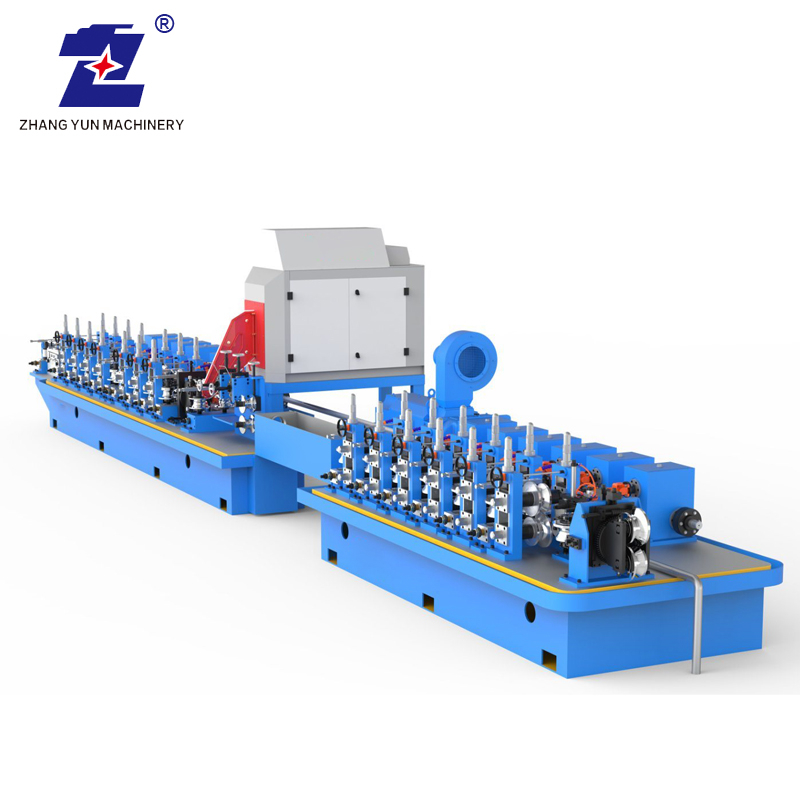

Zhangjiagang City Zhangyun Machinery Manufacturing Co., Ltd. is established in 2002, manufacturer of elevator guide rail processing production line machinery, cold roll forming line machinery and high frequency tube welding line machinery.

Quality Oriented,Technology Innovation is our core concept. Each component of our machines is examined and qualified before assembling; each set of our equipment is fully test run before delivery.