Notes for product customization of cold forming machine

Although the cold bending machine is only five words, but it includes many professional skills, so the need for a full range of level to master and understand it. So that you can understand how to apply it correctly and effectively, and get good practical results, but also to improve our own professional skills.

First, the estimated sales and future sales estimates. Before the cold bending machine customization, we should fully investigate, do a good job of sales forecast, after weighing the feasible plan, start to customize the equipment.

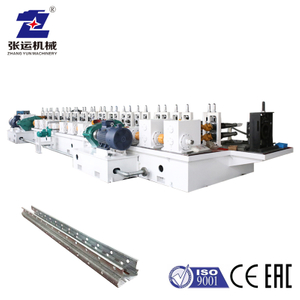

Second, fully understand clearly, the market requirements for the profiles you want to produce, such as the thickness of the material, length, width, material material, requirements of tolerance and appearance, understand clearly these, is customized equipment, must provide information to the equipment manufacturer, in order to make a detailed plan for your equipment customization.

Third, before the customized equipment should determine the procurement of raw material suppliers, determine the material, thickness, opening, in the completion of equipment production, the height of the machine, you can get the test machine materials from the supplier.

Fourth, we should be ready to recruit or train professional boot personnel. This industry, especially boot personnel, must be able to bear hardships, patience, flexible minds can be competent. If the boot personnel is not qualified, it may bring great problems, small problems can not be dealt with, the production of profiles are not qualified, strict waste of raw materials, or improper operation of the machine caused by damage.

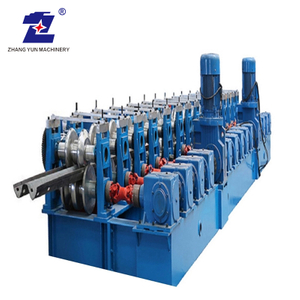

Fifth, when customizing, we should be thoughtful. When signing the contract with the equipment manufacturer, we should list all the requirements clearly and standardize them into the contract, so as not to make unqualified equipment, which affects the production plan and causes losses. There will be no dispute because the contract is incomplete.

Sixth, in the equipment acceptance, should strictly implement the standards, strict control, substandard equipment, the manufacturer is required to do satisfaction, otherwise pull to their own factory, some problems are difficult to deal with. During the acceptance, the main relevant personnel of the project should be brought to the equipment manufacturing plant for acceptance, and the relevant personnel can also learn more professional knowledge from the equipment manufacturer.

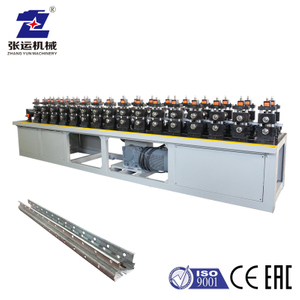

Before buying cold forming machine, you need to do some preparatory work, need to be carefully completed and carried out, if you carry out the work, you can prevent wrong decisions. In the actual job responsibilities, the first thing is to have a clear grasp of the product application natural environment and regulations. The second is to master some basic information of products and manufacturers, to carry out a comprehensive comparison.

Think to choose a high-quality cold bending machine to do the following two points, first to master the application of the requirements, clear the price category of the product, further reduce the selection category. Second, we should choose a professional cold bending machine manufacturer to ensure the quality and performance of the product, to ensure the application of the product.

Cold forming machine can be customized according to different customer regulations or unique customer regulations to consider different customer regulations. There are some special problems in this work, that is, we need to calculate and clarify the price of the product again, because it is a standardized customized product. There is a very good difference between the price of the product and the standard product.

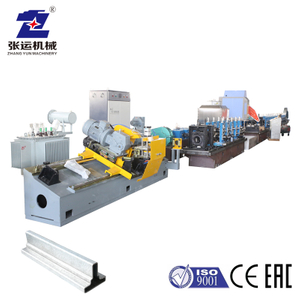

Cold forming machine manufacturers are able to carry out some certification work, mainly quality system management and product quality, which is of interest to the manufacturer. It can improve the competitiveness of itself and its products. In addition, buyers also need to select manufacturers with such verification to ensure the quality and performance of the products.