Zhangjiagang City Zhangyun Machinery Manufacturing Co., Ltd. is established in 2002, manufacturer of elevator guide rail processing production line machinery, cold roll forming line machinery and high frequency tube welding line machinery.

We can undertake the following projects:

1. General Contract of annual output 1,000-500,000tons elevator guide rail machining line.

2. Cold roll forming machines for all kinds of elevator/escalator profiles, such as hollow guide rails, door opening system profiles,stiffeners,upright columns, escalator tracks.

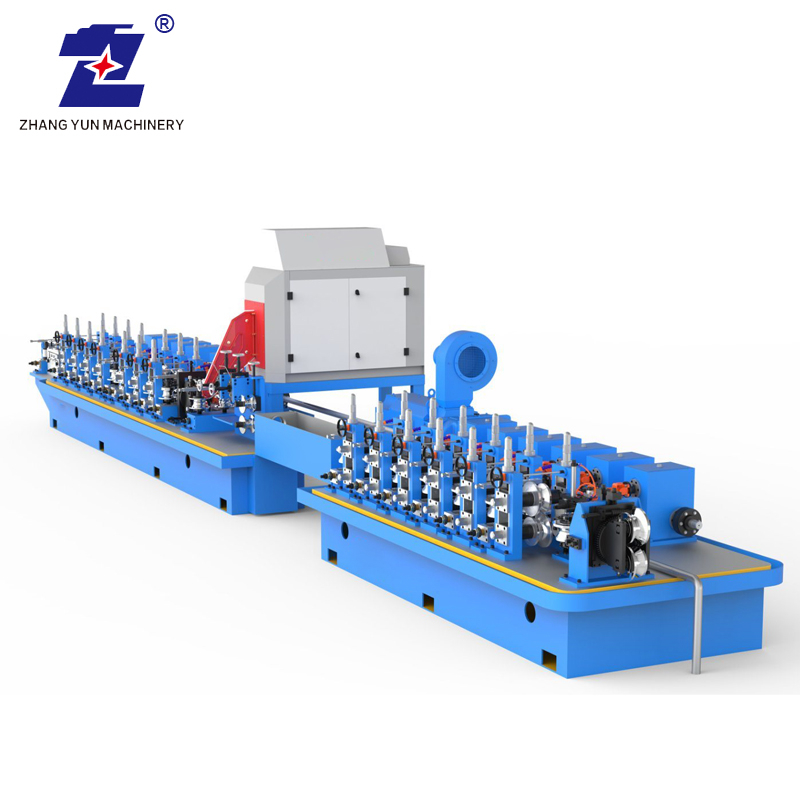

3. HF pipe welding line for pipe Ф10-Ф219mm, thickness 0.3-12mm.

4. Cold-drawn guide rail machines, including pointing machine, cold drawn machine, sawing machine, straightener,milling machine, punching machine,oiling machine,etc.

5. Hot-rolled guide rail processing machines,including twisting machine, straightener, rust remover, painting machine, dryer, planer, large back milling machine, male&female milling machines, CNC driller, countersinking machine,cleaning machine,oiling-filming machine, packing machine,etc.

6. Other non-standard machining equipment, sheet-metal processing equipment.

Quality Oriented,Technology Innovation is our core concept. Each component of our machines is examined and qualified before assembling; each set of our equipment is fully test run before delivery.

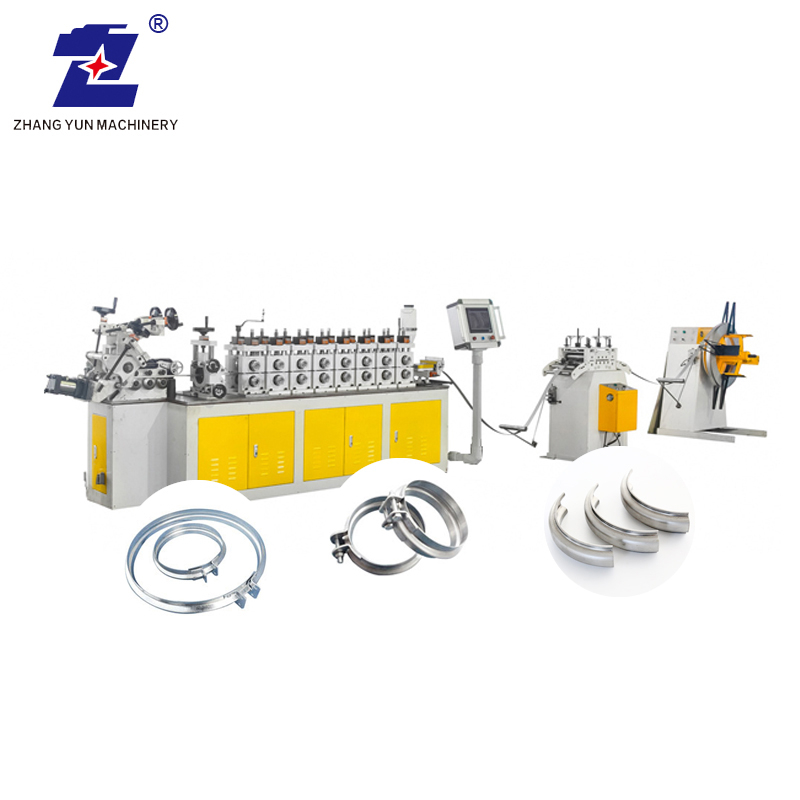

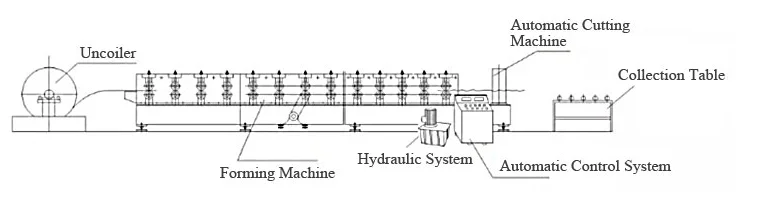

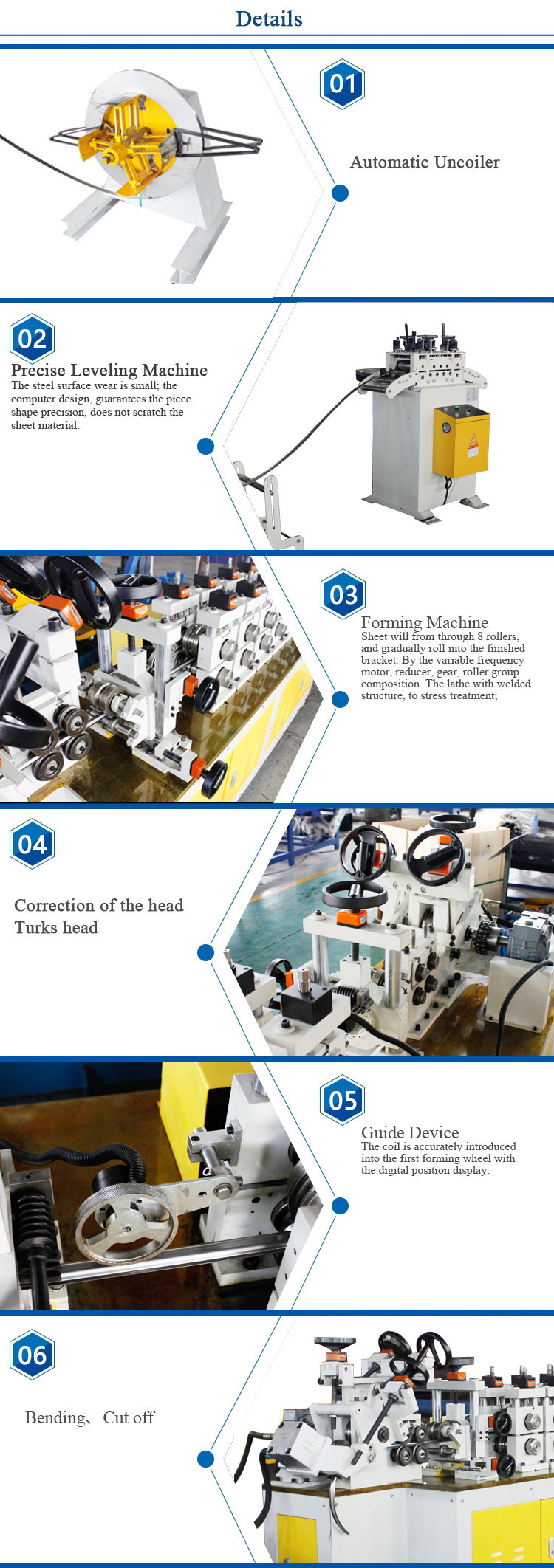

Our company can provide users with advanced cold roll forming machines with multiple materials, thicknesses and shapes, as well as flexible system solutions that integrate welding, punching, tapping, assembly, automatic packaging and other production processes in the cold roll forming process.

Our company is a solid pioneer in the field of customized cold roll forming production automation in China, and provides flexible solutions for the majority of users. These solutions combine more advanced design concepts and laboratory instrument inspection systems.

Over the years, our company has continuously cultivated relevant talents in cold roll forming technology, introduced advanced design concepts, increased investment in scientific inspection systems, and continuously integrated the concept of cold roll forming production automation into all production links of users, providing users in various fields with many successful cold roll forming production cases.

Since its establishment in 2002, our company has been taking "quality-oriented - technological innovation" as the concept, using the perspective of globalization, standing at the commanding height of the industry, seizing development opportunities, seizing market space, and making every effort to build a well-known Chinese brand in the cold roll forming industry of technological innovation.

The high-performance roll forming system designed by our company can process a large number of different kinds of high-quality profiles. The high-quality design team, the modular combination concept of the machine and the precise process production technology ensure the high reliability, safety and economy of the production line. Diverse automation modules and specific supporting technologies enable us to integrate various related production processes to meet the different needs of users. The rapid modular replacement of the machine helps users meet the production needs of single machine and multiple products, and improves the economic performance of the machine in the whole cold roll forming production process.

Vision of the company: through ten years or even longer, Zhangyun machinery will be built into a first-class enterprise of cold roll forming equipment at home and abroad, and finally provide users with perfect flexible system solutions and advanced customized services in the cold roll forming production process.

At present, the equipment has been exported to UK, Romania, Mexico, India and other countries.