Highway guardrails are a critical safety feature on any road system. They are designed to prevent vehicles from accidentally leaving the roadway, which can result in serious injuries or fatalities. Road safety is of utmost importance, and therefore, highway guardrails must be designed, manufactured, and installed with the highest level of quality and precision. This is where the highway guardrail roll forming machine comes in.

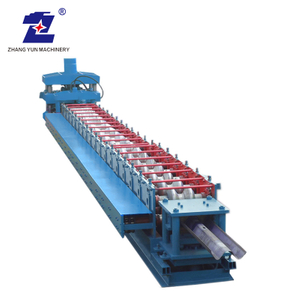

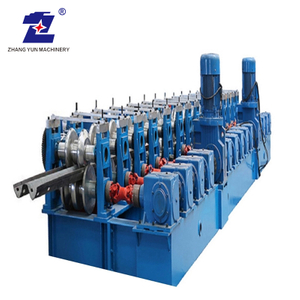

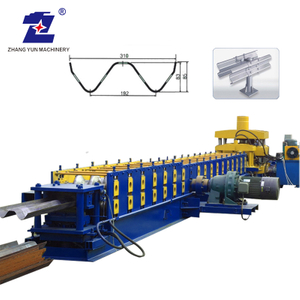

Roll forming machines have been used for decades to produce high-quality and accurate metal products. The highway guardrail roll forming machine is specially designed to produce highway guardrails of various shapes, sizes, and configurations. The machine uses a continuous process of bending and forming metal sheet into the required shape and dimension.

The Highway Guardrail Roll Forming Machine's Components

The highway guardrail roll forming machine is a complex machine that comprises several key components, each of which has a specific role in the production process. The primary components of a highway guardrail roll forming machine include:

1. Decoiler: This component is located at the beginning of the machine, and it's designed to hold and unwind the metal strip or sheet before it enters the roll forming station.

2. Feeding and leveling system: This component is responsible for feeding the metal sheet into the roll forming station accurately, and ensuring that it's levelled and flat.

3. Roll forming station: This is the heart of the machine, where the metal sheet is bent, shaped and formed into the required shape and dimension. The roll forming station contains a series of rollers that are positioned in a specific arrangement to form the metal sheet as it passes through.

4. Cutting system: Once the metal has been formed into the required shape, it needs to be cut to a specific length. The cutting system can be hydraulic or mechanical, and it's designed to cut the metal sheet to the required length.

5. Stacking system: After the metal has been cut, it needs to be stacked neatly to prepare for transportation or further processing.

Key Features and Benefits of Highway Guardrail Roll Forming Machine

1. High Precision: The highway guardrail roll forming machine is specially designed to produce highway guardrails with high precision and accuracy, ensuring that the final product meets quality standards.

2. High Efficiency: The continuous process of roll forming ensures that the machine can produce highway guardrails at a high rate. The production speed can range from 10 to 30 meters per minute dependent on the machine's design and complexity.

3. Versatility: The machine can produce a wide range of highway guardrails, from simple W-beam guardrails to complex shaped guardrails which can be customised according to the client needs.

4. Easy to Operate: The machine is designed with a user-friendly interface and straightforward controls, making it easy to operate even for beginners.

5. Durable and Reliable: The machine is built with high-quality components and materials that are resistant to wear and tear, making it durable and reliable over many years of use.

6. Cost-effective: Highway guardrail roll forming machines offer a cost-effective solution for producing highway guardrails since they eliminate the need for labour-intensive manual production methods.

Why Highway Guardrail Roll Forming Machine for Road Safety?

1. Enhance road safety: Highway guardrails are a critical safety feature on roads, and they help to reduce fatalities and injuries by preventing vehicles from leaving the roadway.

2. High-Quality Standards: The highway guardrail roll forming machine produces guardrails to strict quality standards that ensure optimal performance and durability.

3. Precision production: The continued use of the highway guardrail roll forming machine guarantees the production of the same high-quality guardrails whether it be W-beam, U-beam or any other shape, with no variance in shape or quality.

4. Cost-effective production: Highway guardrail roll forming machines offer a cost-effective solution for producing highway guardrails since they are automated, reducing the need for manual production methods.

5. Durable guarding: Highway guardrails made through the roll forming machine can withstand strong impacts and harsh weather conditions, reducing the need for frequent replacement and repair.

Conclusion

Road safety is a critical aspect that cannot be compromised. It's essential to ensure that all road systems have appropriate highway guardrails installed to prevent accidents, injury, and fatalities. The highway guardrail roll forming machine is a specially designed machine that produces high-quality and precise highway guardrails that meet all quality standards. Using this machine provides a cost-effective solution, saves time, increases productivity, and ensures optimal road safety. Therefore, investing in a highway guardrail roll forming machine is not only essential but also beneficial in the long term.