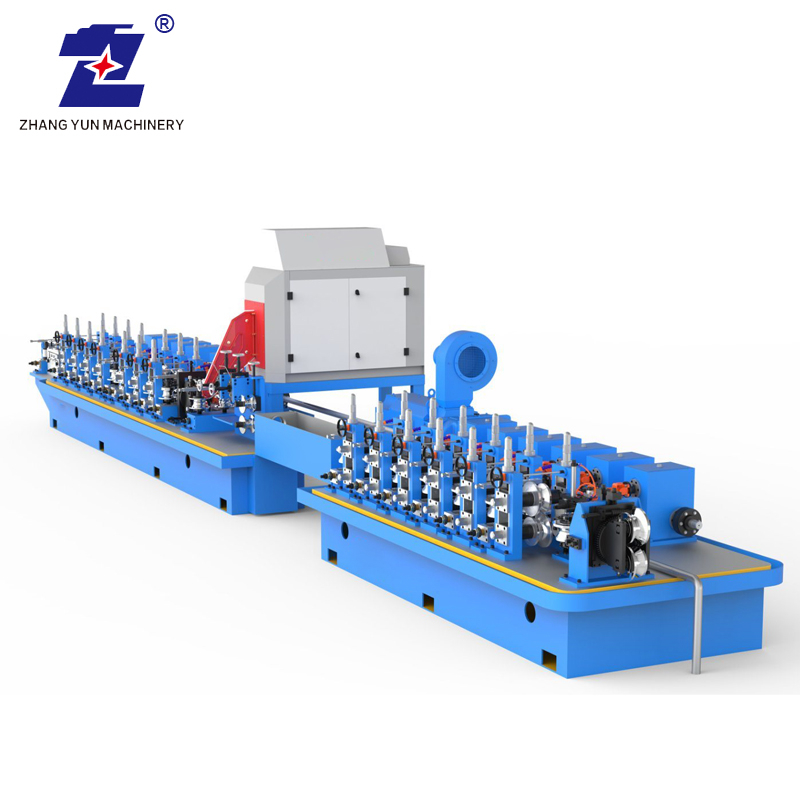

This machinery is integrated into the design and manufacturing for many years of our experience, including the design concept and advanced processing technology. The equipment is good in stability. Our products can totally automatic control, convenient operation, high efficiency. Our machinery can produce many type of products, such as cut off type and pressure type.

The C Z Purlin Roll Forming Machine can produce C and Z profiles. Produce the C and Z purlin by exchange one side of the roller up and down. Greatly improved the production efficiency and save the working space. The driving way is chain drive. Our C / Z channel purlin roll forming machine can be profile custom, and are lower cost, high efficiency, reliable working ,low energy consumption. We can do any type of equipment according to customer requirements.

This machinery is integrated into the design and manufacturing for many years of our experience, including the design concept and advanced processing technology. The equipment is good in stability. Our products can totally automatic control, convenient operation, high efficiency. Our machinery can produce many type of products, such as cut off type and pressure type.