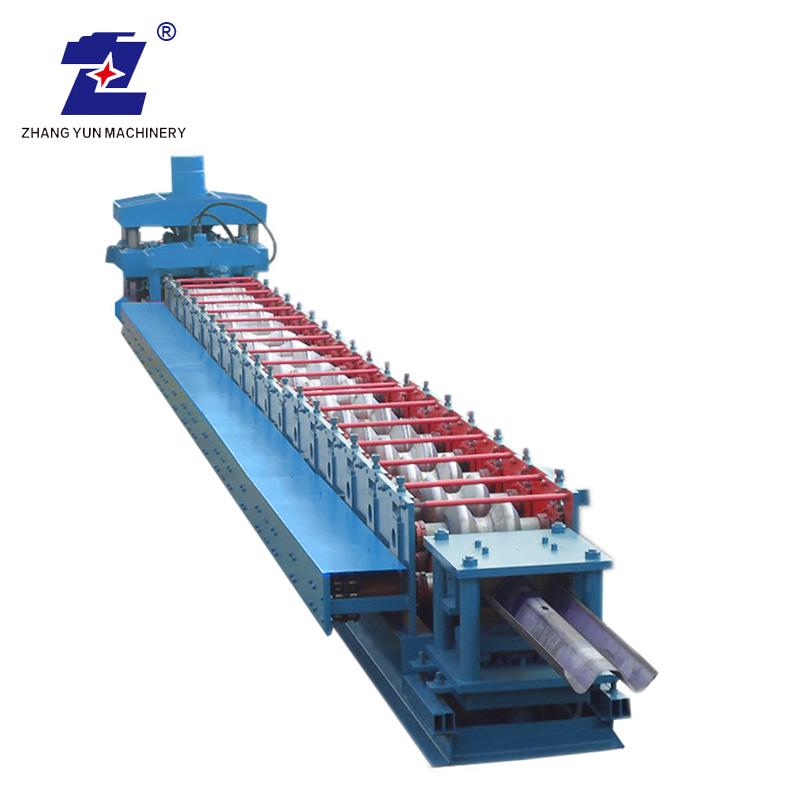

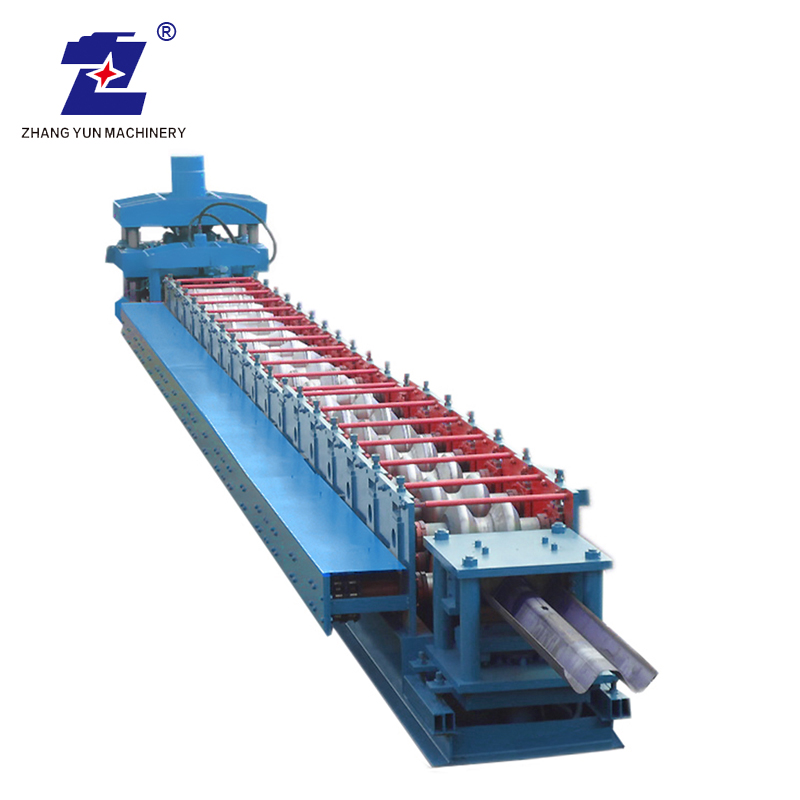

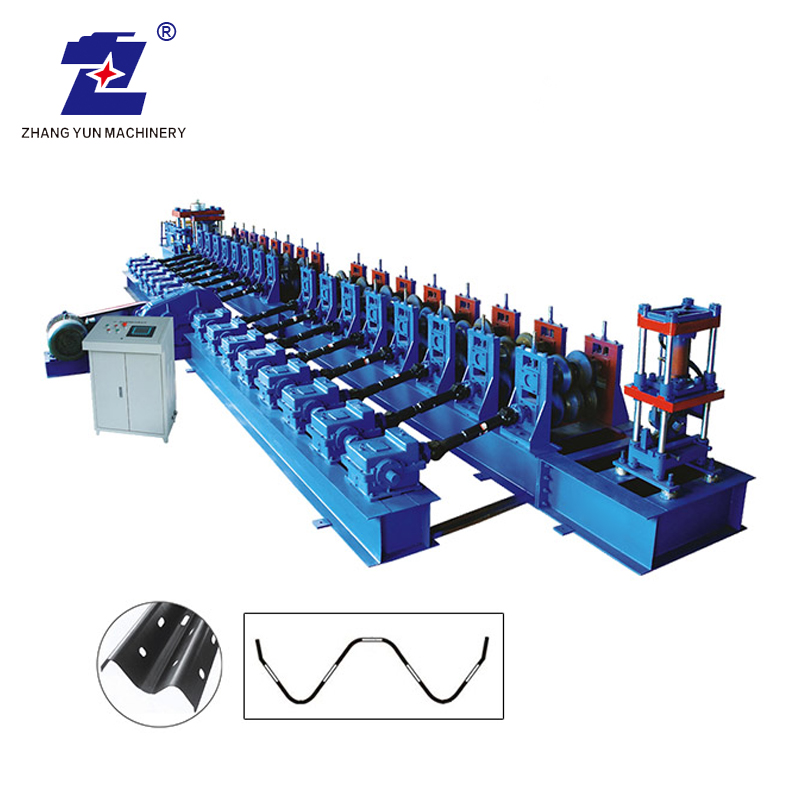

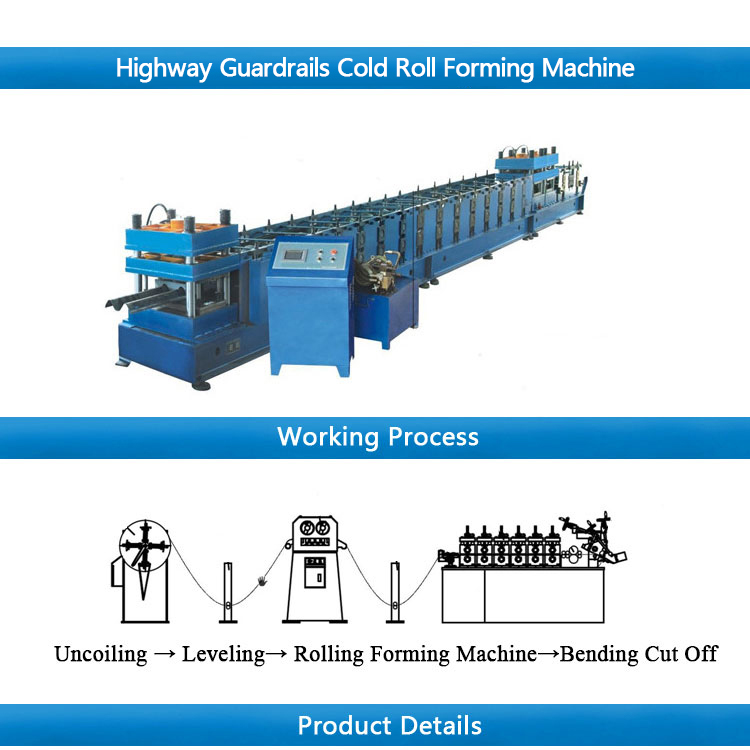

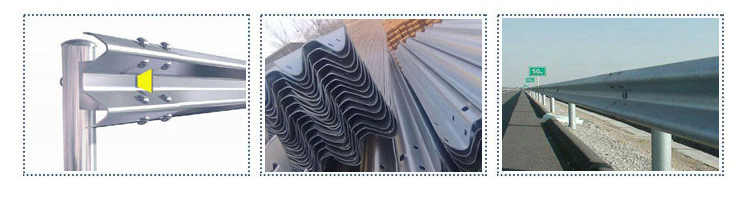

Guardrail Panel Cold Roll/Rolling Forming Machine

Technical Specifications

1. Decoiler

With two tapered electric bulgy clamps, and its carrying capacity is 8 tons. The inner diameter of the roll material is about 500 to 600mm, the maximum diameter of steel coil is 1800mm. Clamp motor power is 2.2kw with 4-pole normal motor. Adopt ZQ250 speed reducer, its speed ratio is 31:5.

2.Leveling Machine

Wallboard seven-roller leveler with two-roll pinch and five-roll leveling. Leveling roller diameter is 110mm. The leveling machine before and after has vertical guide roll. Feed inlet port equipped with nip rolls.

material: 40Cr, quenched hardness: HRC48°~52°, motor power:7.5kw, 6-pole normal motor, ZQ350speed reducer, speed ratio: 20:49, φ200 arrester brake.

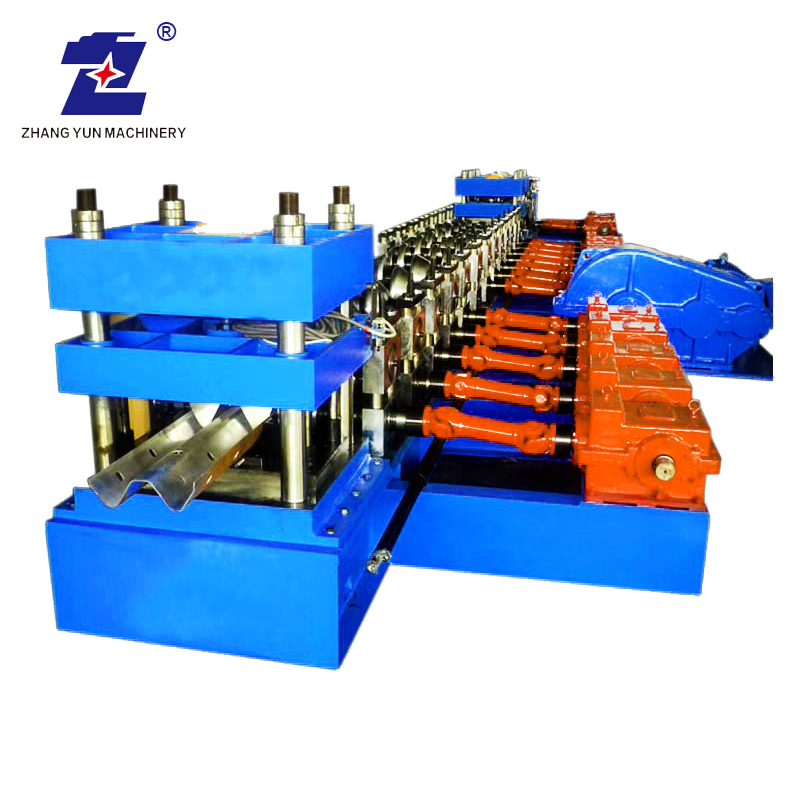

3.Punching Machine

Adopt YL32-315 four-column hydraulic punching machine, and hydraulic station motor power is 22kw. One set of two waves guardrail plates punching cutting die, design and process mainly according to users' design drawings. The material of mold inserts and plunger chip is Cr12MoV alloy steel. The punching machine before and after equipped with adjustable guide roll. (guide roll material: Cr12MoV, hardness: HRC58º~60º) Besides, it also equipped with a set of spare blade and plunger chip.

4.rapid feeding material mechanism

It has two pairs of feeders and requires two becomes one.

pinch automatically, motor power:2.2 kw, ZQ250 speed reducer, hand-turn compressing

5.Photoelectric Length-measuring Device

number: two pairs, cut length: 4320mm, length accuracy< ±3.0mm

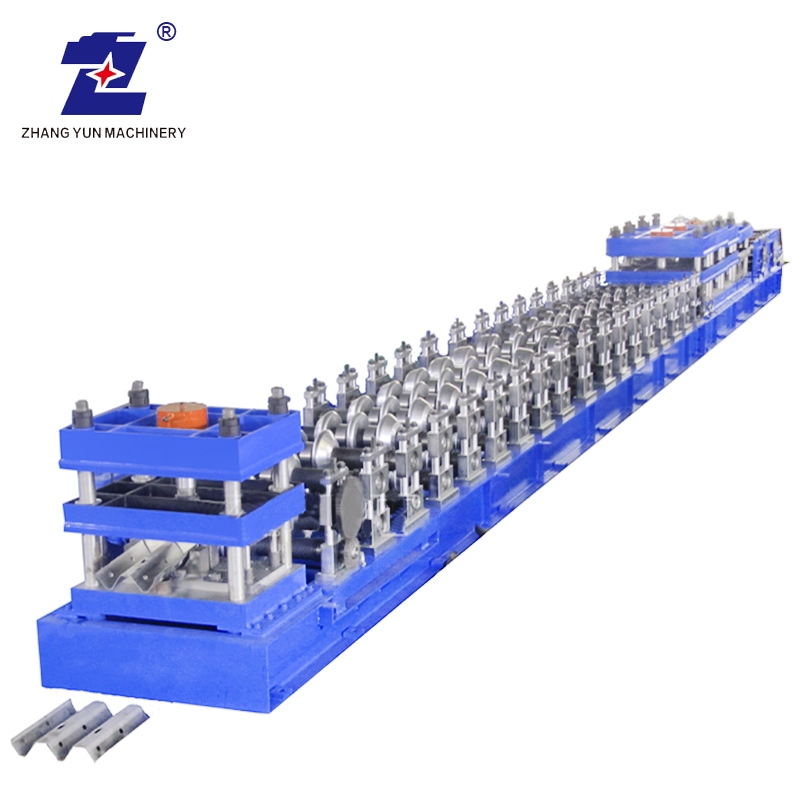

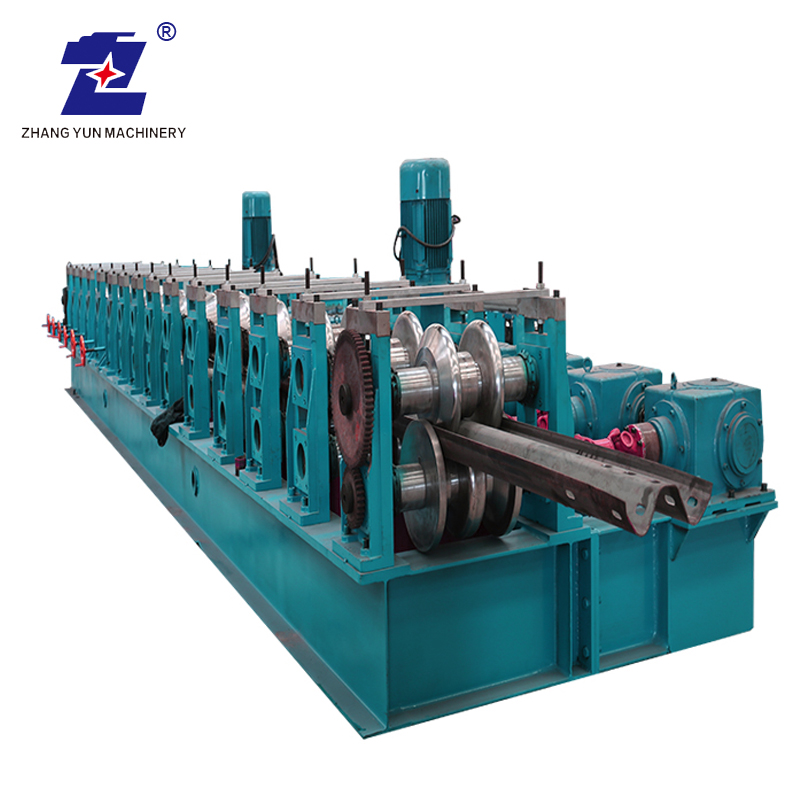

6. Main Forming Engine

This unit includes 11 molding processes with independent open arch structure.

The mechanical spreading width : 550mm.

Arch material : HT200 , tempered.

The column cross-section size: 80 x 70, with sufficient strength and reliable quality assurance. Vertical guiding roller numbers: 3

Roller diameter of vertical guiding roller: 80

Material: 40Cr steel, quenched and tempered.

Bearing type: Fixed surface 7216, regulation 32216, each has 4.

Numbers of dual-axis gear box: 1

Numbers of single-shaft transmission gear box: 9

Bevel modulus: M=9

Gear box material: HT200.

Host power: 45KW r, electromagnetic speed regulating,

Speed reducer: ZQ650

Speed ratio: 48.57

Use 1 inch double chain drive between the transmission gear box ; universal transmission shaft between the roller shafts, and the universal transmission shaft type is140-275. Use 1.5 inch dual chain drive between the speed reducer.

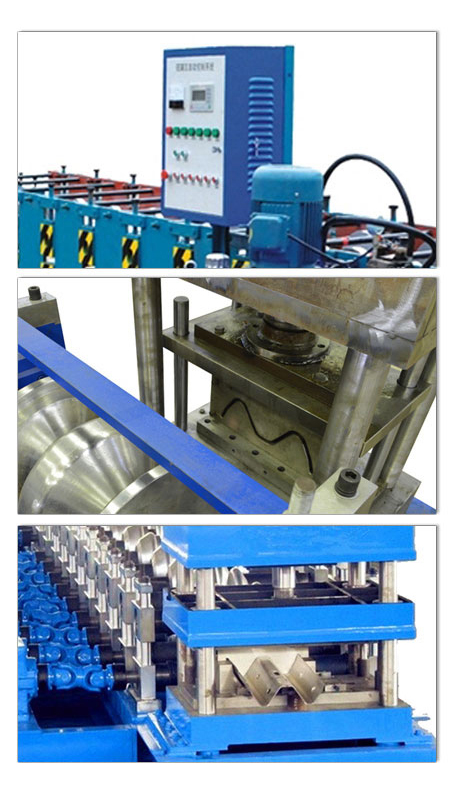

7.Forming Mold

A set of two wave guardrail plate roll forming die, designed and processed according to the national standard. The material is GCr15, and the overall quenching hardness is HRC58°~ 62°.

8.material Receiving Platform

Roller type material receiving station, 5m length, 6# steel welded.

9.Control System

Common control system. Can manually and automatically control the harmony of various parts of of the whole production line.

10.Others

The equipment total power is 78.9Kw, with 30000mm * 4000mm length * width. The maximum rolling height is 85mm, the maximum rolling thickness is 4.0mm, and the maximum rolling speed is 3 ~ 12m/min. Structural materials of welding machine seat must meet the requirements, welding must be up to the national standard . Equipment after rust cleaning should be firstly coated with steel special anti-rust paint comprehensively covering, and then coated with high quality topcoat. The rotating part should be divided by warning color.