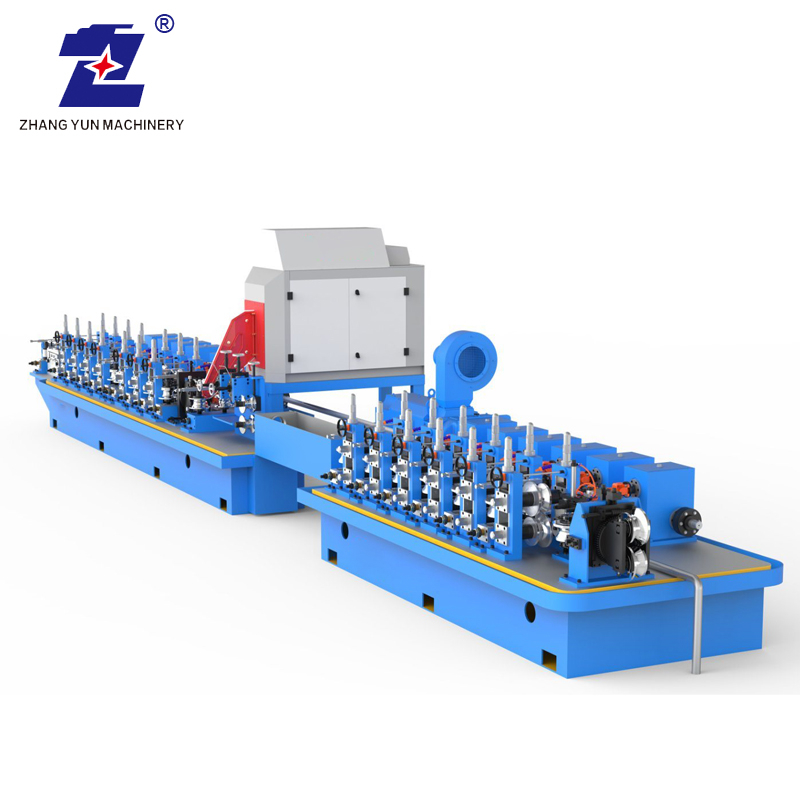

This line is designed to produce various types of elevator guide rail. The elevator guide rail production line has the characteristics of high accuracy and straightness, and our machines can produce different elevator guide rails according to customers' drawings.

Some machine's introductions of elevator guide rail manufacturing equipment

Lift guide rails are essential components in the installation of elevators in buildings and other structures. They serve as guides for elevator carriages as they move up and down along the shaft and ensure safe and smooth transportation of people and goods. Manufacturing lift guide rails requires precision and accuracy to ensure that they meet the required safety standards. Therefore, it is essential to implement a high-quality lift guide rail processing production line.

A high-quality lift guide rail processing production line comprises various stages that aim to produce guide rails that meet strict industry standards. The following is a description of each stage:

1. Cutting

The first stage of the lift guide rail processing production line is cutting. This stage involves cutting the raw material (usually steel) into specified lengths depending on the required size of the guide rails. To achieve accurate cuts, a CNC (computer numerical control) cutting machine is used. This machine is programmed to make precise cuts based on the specifications inputted into the system.

2. Milling and Drilling

After cutting, the guide rails are sent to the milling and drilling stage. In this stage, the rails are shaped and drilled to the required specifications. Milling machines are used to shape the rails, while drilling machines are used to create holes where bolts and screws will be used to attach the rails to the elevator shaft. Both machines are fitted with precision tools that ensure accurate shaping and drilling of the guide rails.

3. Grooving and Tapering

The next stage in the production line is grooving and tapering. This stage involves creating grooves on the guide rails to improve their stability during vertical movement. The grooves are created using special tools that remove metal from the rails' surface. Tapering, on the other hand, involves reducing the width of the guide rail towards the top to allow easy entry and exit of the elevator carriage. Tapering is done with precision tools that ensure the rails maintain their shape and strength.

4. Straightening

After grooving and tapering, the guide rails may have slight bends that can affect their effectiveness. Therefore, the rails are subjected to a straightening process to ensure they are perfectly straight. The rails are passed through a straightening machine that applies pressure to them at specific points to straighten them out.

5. Welding

The next stage in the production line is welding. In this stage, individual guide rails are welded together to create a complete set. Welding is done using MIG (Metal Inert Gas) welding machines that ensure strong and durable joint connections.

6. Finishing

The final stage in the production line is finishing. This stage involves cleaning, painting, and marking the guide rails with essential information such as their size, weight, and manufacturer details. The rails are inspected to ensure they meet the required safety standards before being packaged for shipping.

Production Capacity

230400pcs/year (300days/year; 2shifts/day, 8hours/shift) based on T89B/5m

| No. | Description | Model | Qty |

| 1 | Automatic Twisting Machine | ZY-ZDJNJ-II | 1 | set |

| 2 | Automatic Straightening Machine | ZY-ZDJZJ-I | 2 | sets |

| 3 | Rust Removing Machine | ZY-CXJ-II | 1 | set |

| 4 | Painting Machine | ZY-YQJ-II | 1 | set |

| 5 | Drying Room | ZY-HF-II | 1 | set |

| 6 | Planer | ZY-B2016 | 3 | sets |

| 7 | Chip Remover | ZY-PXJ1000 | 1 | set |

| 8 | Automatic Detection Machine | ZY-ZDJCJ-I | 1 | set |

| 9 | Automatic Straightening Machine | ZY-ZDJZJ-I | 2 | sets |

| 10 | Milling Machines | ZY-JGSCX-II | 2 | sets |

| Female Milling Machine | ZY-JGSCX-II | 1 | set |

| Male Milling Machine | ZY-JGSCX-II | 1 | set |

| Drilling Machine | ZY-JGSCX-II | 2 | sets |

| Double-head Countersink Drilling Machine | ZY-JGSCX-II | 1 | set |

| One Conveyor Line | ZY-JGSCX-II | 1 | set |

| 11 | Oiling And Filming Machine | ZY-TYTMJ-II | 1 | set |

| 12 | Transverse Conveyor (A) | ZY-HYJ-II | 9 | sets |

| 13 | Jack traverse Converyor (B) | ZY-DSJ-II | 17 | sets |

| 14 | Longitudinal Conveyor (C) | ZY-ZXJ-II | 8 | sets |

| 15 | Independent Roller | ZY-DLJ-I | 1 | set |

| 16 | Control System |

| 1 | set |

Zhangjiagang City Zhangyun Machinery Manufacturing Co., Ltd. is established in 2002, manufacturer of elevator guide rail processing production line machinery, cold roll forming line machinery and high frequency tube welding line machinery.

Quality Oriented,Technology Innovation is our core concept. Each component of our machines is examined and qualified before assembling; each set of our equipment is fully test run before delivery.

FAQ

1.Q: Are you manufacturer or trading company?

A: We are manufacturer. And we have our own import & export rights.

2.Q: What info you need before you make proposal?

A:Your target type of elevator guide rails; your required production capacity per year; working hours per day, working days per year.

3.Q: What is the MOQ?

A: One set.

4.Q: Do you provide installing and debugging overseas?

A: We send engineers overseas for installation and debugging under client’s request. On line guiding and technical support is for life time.

5.Q: Can you make the machines according to my design or prototype?

A: Yes. We have an experienced engineering team for working out the most suitable design and production plan for the machines you are going to book with us.We can also make the machines according to your design or prototype.

6.Q: How does your factory do regarding quality control?

A: We have Quality Management System Certificate GB/T9001-2016/ISO9001:2015. Each component of our machines is examined and qualified before assembling; each set of our equipment is fully test run before delivery.

7.Q: How can I trust you that machines have passed test running before shipping?

A: 1) We record the test running video for your reference.

2) You are welcomed to observe the test running in our factory.

8.Q: What about your after-sale service?

A: 1) We have an after-sale service team for each customer, including GM, sales Rep, chief engineer, and main engineers for design and making your machines.

2)Overseas after-sale service is available.

3)We provide life time online technical support.

9. Q: What should I do if I just start a new business?

A: Contact us immediately,we provide free consultant pre-sales service.

We are domestic leading factory in elevator guide rail processing equipment field. We are familiar with our machines and we have many successful user cases. We know the development history and the latest trends. We can make the most reasonable proposal for you.

10. Q:Can I visit you factory to check machines on-site?

A: We are manufacturer, we have our own R&D department and workshops for more than 20 years. We warmly welcome your visit and checking machines in our factory.