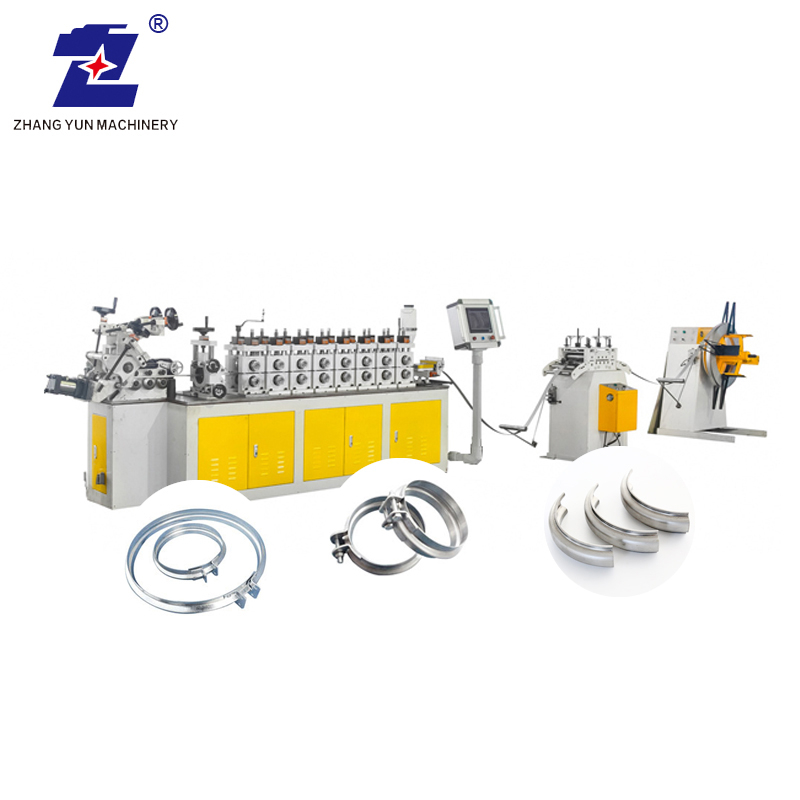

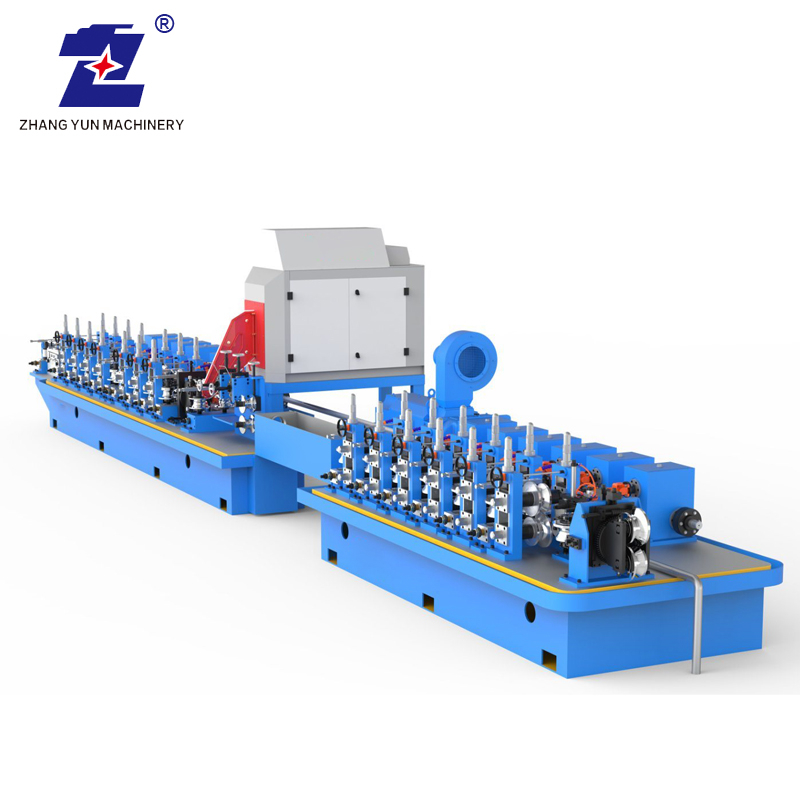

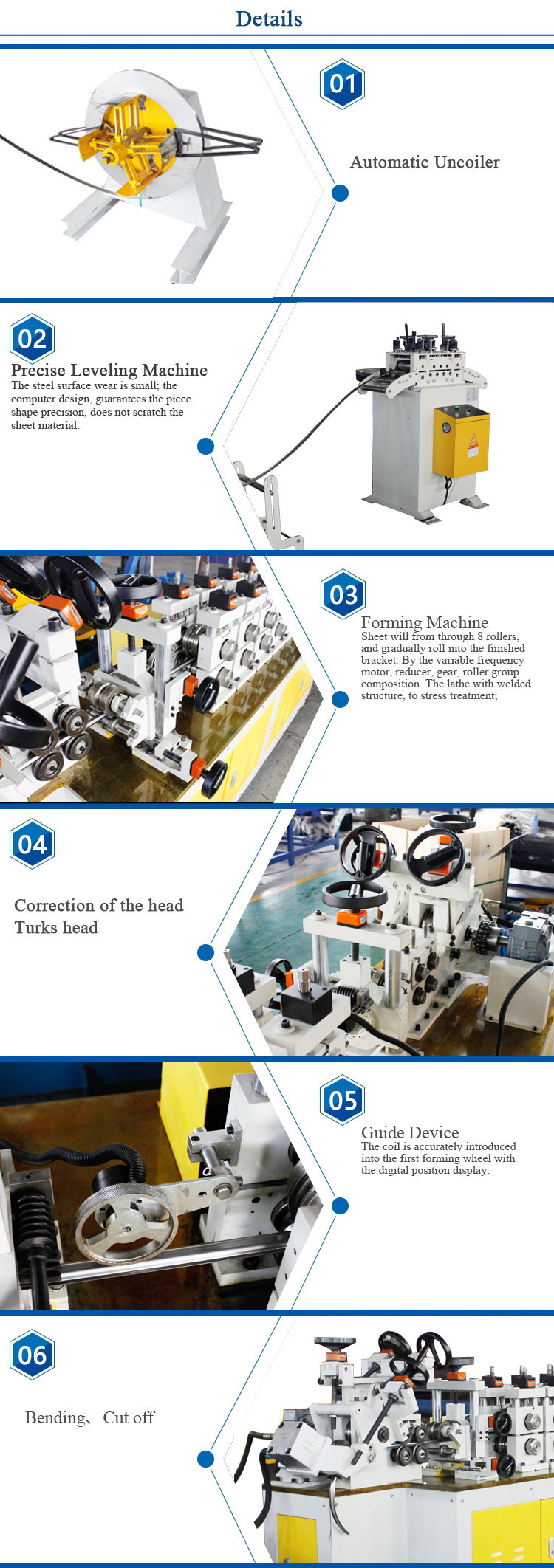

The automobile profile cold roll forming machine integrates our many years of design and manufacturing experience, advanced design concept and processing technology. The equipment has good stability, and the products produced are stable and high precision. Overall automatic control, convenient operation and high efficiency.

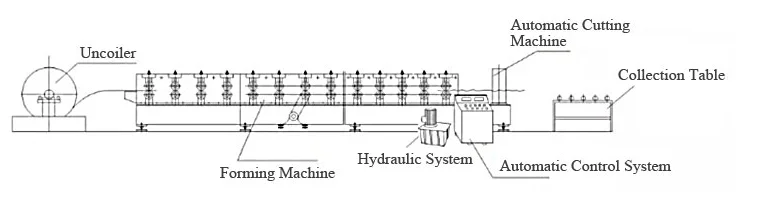

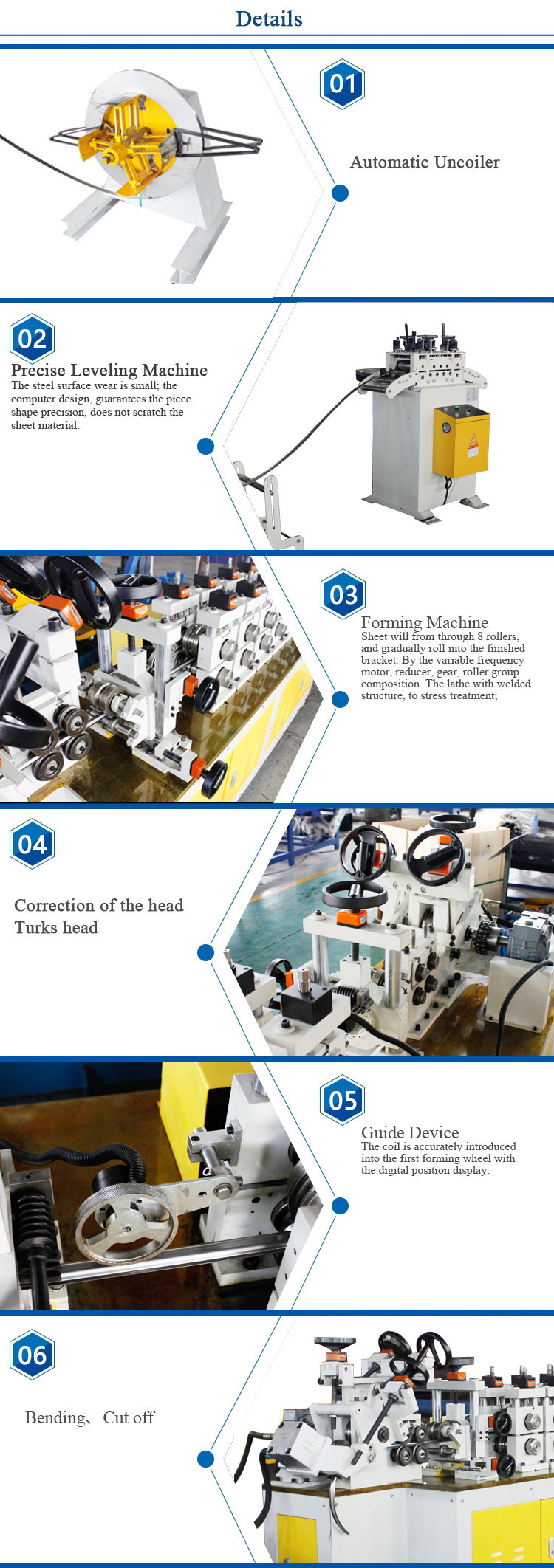

Uncoiling →Leveling→Rolling Forming Machine→ Bending,cut off

Equipment Specifications

| Feeding Direction | From Right to Left |

| Voltage | 380V, 3Phase, 50Hz |

| Roller die material | Cr12, quenched, hardness about HRC60°46# |

| Gear Oil | 18# Hyperbolic gear oil |

| Strip material material | Q235/SUS304 |

| Width of Strip | 80 mm~300 mm |

| Thickness of Strip | 0.5 mm~1.5 mm |

| Mill length | ≤10 m |

| Rolling Speed | 0~20 m/min |

Zhangjiagang City Zhangyun Machinery Manufacturing Co., Ltd. is established in 2002, manufacturer of elevator guide rail processing production line machinery, cold roll forming line machinery and high frequency tube welding line machinery.

We can undertake the following projects:

1. General Contract of annual output 1,000-500,000tons elevator guide rail machining line.

2. Cold roll forming machines for all kinds of elevator/escalator profiles, such as hollow guide rails, door opening system profiles,stiffeners,upright columns, escalator tracks.

3. HF pipe welding line for pipe Ф10-Ф219mm, thickness 0.3-12mm.

4. Cold-drawn guide rail machines, including pointing machine, cold drawn machine, sawing machine, straightener,milling machine, punching machine,oiling machine,etc.

5. Hot-rolled guide rail processing machines,including twisting machine, straightener, rust remover, painting machine, dryer, planer, large back milling machine, male&female milling machines, CNC driller, countersinking machine,cleaning machine,oiling-filming machine, packing machine,etc.

6. Other non-standard machining equipment, sheet-metal processing equipment.

Quality Oriented,Technology Innovation is our core concept. Each component of our machines is examined and qualified before assembling; each set of our equipment is fully test run before delivery.